Jigs and JIGs are an indispensable product in the mechanical manufacturing industry. Referring to jigs, JIG refers to the task of clamping, positioning details, and its products. Types of jigs are designed and manufactured mainly to serve 3 tasks with 3 corresponding classification names: processing jigs, assembly jigs and inspection jigs.

Jigs and jigs help ensure product quality during processing, assembly, and inspection. It is the first basis for other indicators to be generated and have the correct value if the fixture is correct. The first application of jigs is for processing – Machining jigs.

What are the benefits of a good jig set for machining?

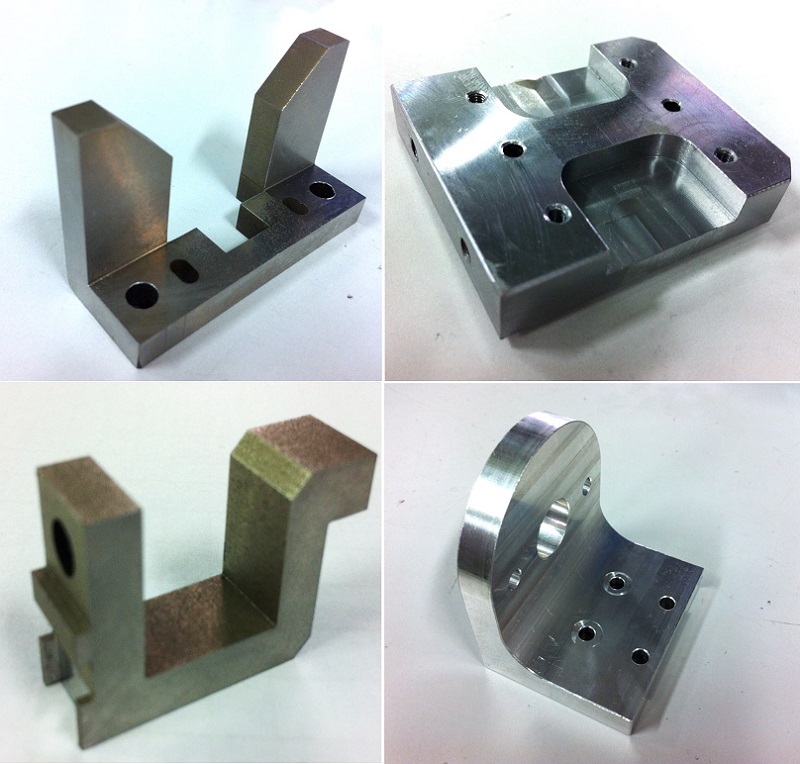

The functions and benefits of using this type of jig are true to its name. Specifically, the presence of jigs and JIGs before, during and after the machining process (milling, turning, wire cutting, waterjet cutting…) to position parts and workpieces, and maintain that position. throughout the machining process. From there, the machining program can use the original coordinates as a standard. Determine the exact position of the work piece relative to the cutting tool during machining. Using good and optimal machining jigs not only helps meet machining conditions, but it also helps operations be performed easily and quickly, reducing jig time.

Characteristics of jigs for machining manufactured by V-Coating

Characteristics of jigs for machining manufactured by V-Coating

V-Coating is a unit with many years of experience in designing and manufacturing jigs in Vietnam. Our jig designs are always simulated and optimized on 3D software before being put into actual manufacturing, to simplify the design, make it easy to use for operators while still ensuring accuracy. accurately throughout the working process.

Our machining jigs are always responsible for positioning and clamping the machined parts with outstanding features:

– Achieve high accuracy. Because all parameters in the machining program will not be accurate if the fixture does not meet standards.

– Can easily, quickly and flexibly change parts according to the requirements of each type of processed product (with jigs used for processing many different product models).

– Holds parts firmly before, during and after machining.

– Has enough rigidity, ensuring the requirements of clamping force, torque, reaction force generated during the cutting process from the main shaft, machine table, knife head…

– For milling, turning, wire cutting, and waterjet cutting products using coolant oil solution, cutting oil, oil immersion, acidic, basic, high temperature environments, using chemicals, and continuous disassembly. Continue… the selection of materials for the positioning and guiding elements of the fixture… must have good abrasion resistance and long-term use. These requirements are always calculated during V-Coating’s design process.

Characteristics of jigs for machining manufactured by V-Coating

Characteristics of jigs for machining manufactured by V-Coating