All products produced, assembled, and manufactured after each stage and before being shipped are subjected to inspection stages (QC-quality control). Depending on the type of product and its application, inspection can be done only by eye (visual test) or by measuring geometric parameters (length, width, roughness, gloss, weight). …), test mechanical, chemical and physical properties (stress, strength, gas concentration…) to determine tolerances and errors compared to the design and required standards of the finished product.

In order for testing to yield accurate, clear results and for quick and convenient testing, using testing fixtures for products is essential. Depending on the requirements for testing different parameters, there will be different types of measuring jigs and testing jigs to serve these purposes.

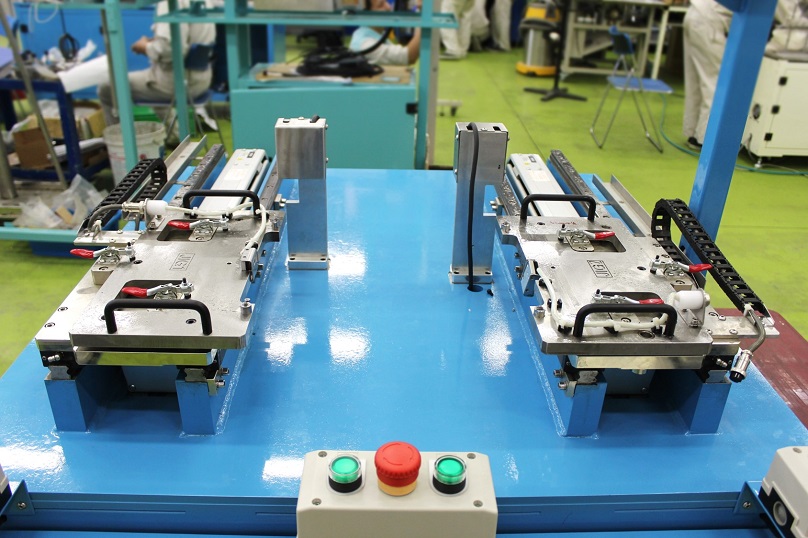

Also depending on those requirements, there will be different types of simple to complex fixtures with structures ranging from purely mechanical structures to the presence of pneumatic and hydraulic clamping devices. , servo motor, travel sensor, position, calculator and report output parameters…

What are the benefits of a good set of jigs and jigs for measuring and testing?

Testing and measuring jigs help determine product parameters to compare with output standards and customer requirements. A test jig is designed and manufactured with an optimal solution that provides accurate and clear results from measurements. Helps the inspection department quickly determine whether the product meets requirements or not. The inspection process takes place with high accuracy and productivity, helping to reduce product costs and improve business competitiveness.

Characteristics of testing fixtures designed and manufactured by V-Coating

V-Coating is a unit with many years of experience in designing and manufacturing jigs for testing in Vietnam, the Philippines, India… Testing jigs can be used alone or integrated into measuring machines, and automatic testing in inspection lines.

Our jig and JIG designs are always simulated and optimized on 3D software before being put into actual manufacturing, in order to simplify the design, make it easy to use for operators while still ensuring accuracy throughout the working process.

We specialize in providing all kinds of testing jigs for automatic machines and lines. Jigs for checking flatness, checking coaxiality, concentricity, measuring and checking friction, fatigue testing, static load testing, dynamic load testing for electric motorbike frames, cars…

Our assembly jigs have outstanding features:

– Achieve high accuracy, reliable measurement results. We build the geometric and technical parameters of the fixture based on the customer’s input and output product requirements. Sensors, measuring heads, meters, cylinders… are all branded products from Europe and Japan (can be customized according to customer needs and investment level).

– Can install and disassemble products before and after testing easily, quickly and flexibly change for each type of product to be tested (easy DANDORY with fixtures for testing product models different). Our inspection jigs will help customers significantly reduce the cycle time of the QC process, providing higher productivity and reducing labor costs.

– Has enough rigidity, ensuring the requirements for clamping force and reaction forces generated during measurement and testing.

– Providing customers with optimal and modern automation solutions in testing. By the combination of components: jig, bar feeding assembly, robot arm, measuring head assembly, display screen, control chip, calculate and output the output value, giving results in real time. a few seconds.

– Products that need to be assembled in a clean room environment or special environment, the choice of materials for the positioning and guiding elements of the jig… must have good abrasion resistance and have a long usage time. Long, heat resistant, moisture resistant. These requirements are always calculated during V-Coating’s design process. Ensuring durability and long life of jigs in the line.