What is CNC wire cutting machining?

EDM wire cutting, also known as electric spark machining, is a special machining method that uses metal corrosion using electric sparks. In CNC wire cutting with electric spark, the tool and the part are two electrodes.

In which the cutting wire is the Catode and the part plays the role of the Anode. The movement of the cutting wire is controlled along a contour located in the XY Cartesian coordinate system. The machine table is CNC controlled to create movement in the X and Y directions. Combining the secondary movement of the two upper and lower wire guides along the U and V axes creates a wire tilt angle that helps the machine cut taper corners. depending on the thickness of the workpiece and the machine’s ability to cut taper angles. The movement of the cutting wire can be started from the outside of the workpiece and enter the position to be cut, or the wire can be threaded through the hole through the thickness of the workpiece.

The cutting process is the process of running XY and UV interpolated wires according to the programmed contour on the control screen. The position of the cutting wire is displayed with direct coordinates and simulated images to help users easily. Easily control the cutting process.

| TT | Machine name | Model | Quantity | Manufacturer | Machine journey |

| first | Electric pulse machine | AD53L | first | SODICK | 600*400*400 |

| 2 | Electric pulse machine | AD3L | first | SODICK | 300*250*250 |

| 3 | Electric pulse machine | EGD2 | first | SODICK | 300*250*300 |

| 4 | Electric pulse machine | AM35L | first | SODICK | 350*250*250 |

| 5 | Electric pulse machine | A35 | first | SODICK | 350*250*300 |

| 6 | Wire cutters | AQ600L | first | SODICK | 600*400*350 |

| 7 | Wire cutters | VL400Q | first | SODICK | 400*300*250 |

| 8 | Wire cutters | U3 | first | MAKINO | 370*270*220 |

| 9 | Wire cutters | AQ600L | first | SODICK | 600*400*300 |

| ten | Wire cutters | AQ325L | first | SODICK | 350*250*220 |

| 11 | Wire cutters | 5 | SUNTECH | 600*400*400 |

List of pulse machines and EDM wire cutting machines for V-Coating’s precision CNC machining

CNC wire cutting machining methods

Currently there are two CNC wire cutting processing methods with names based on the material of the cutting wire, respectively molybdenum wire cutting and copper wire cutting:

Molybdenum wire cutting (molybdenum, molybdenum, saw wire cutting) is widely used with the advantage that the investment cost for cutting wire materials is not too high, molybdenum wire can be used to cut over and over again. The quality of the surface cut with molyb wire ensures the processing of detailed surfaces and molds that do not require too high precision.

Copper wire cutting provides a highly polished surface, suitable for high precision requirements in high-end molds and machine parts that require precision and rigorous surface quality. However, the investment cost and cost of cutting wire with copper wire is significantly higher than cutting with molybdenum wire.

Advantages of CNC wire cutting processing at V-Coating

Machining details using CNC EDM wire cutting is a special processing method that can be used for details with large thickness (up to 300, 500mm…)

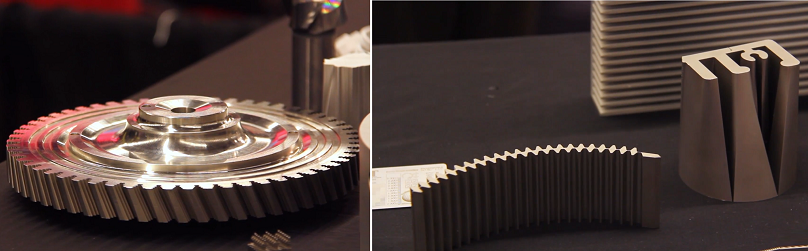

Wire cutting profiles can be guaranteed according to complex 2D design drawings, narrow grooves and small holes. Machining right angles, or sharp edges, complex curves, with variable clearance and cutting thickness.

Special machining materials with high hardness that are difficult, not optimal or impossible to process with other machining methods.

Wire cutting is also very suitable for machining simple parts with small thickness. Multiple products can be cut at the same time easily when stacking thin sheets on top of each other. And cut special details, cut mold wire, cut wire of all kinds of mortar and pestle… as required.

The cost of molybdenum EDM wire cutting and copper wire cutting is flexibly supported by V-Coating for customers, depending on the order quantity, complexity of details and tolerance requirements, and surface gloss required by the customer. .